Effective Personal Protective Equipment Program

A PPE program must be comprehensive.

All levels of an organization from senior management to the front-liners must all participate and commit to the implementation of a good PPE program.

Because it’s more than just a general procedure. Basically, a Personal Protective Equipment program that is fully practical includes the following:

- Risk assessment

- Appropriate controls selection

- PPE selection

- Fitting

- Training

- Management support

- Maintenance

- Program audit

STOP!! Conduct a risk assessment first.

The first step in the development of a PPE program is to identify the hazards at the worksite.

What you can examine are as follows:

- Work practices

- Processes

- Job procedures

- Equipment

- Products

- Layout

- Individual factors

Some jobs need more PPE than others.

That’s why particular attention should be paid to job requirements as some types of hazards require more than one piece of Personal Protective Equipment.

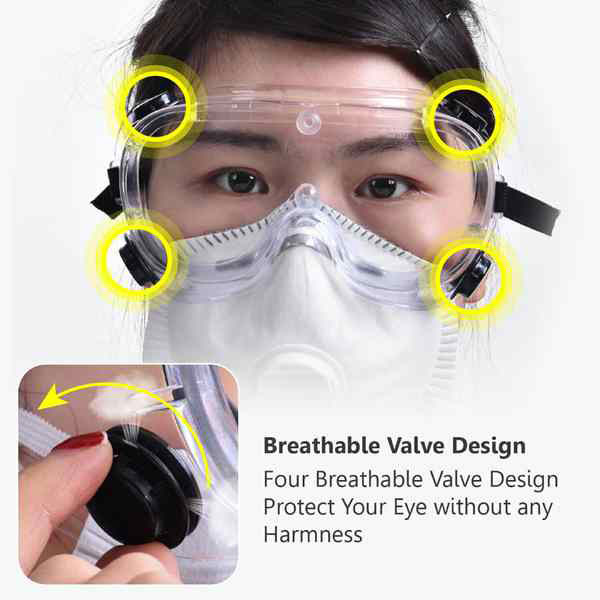

Especially those working in laboratories exposed to chemical hazards. For example, lab workers require medical PPE like anti-fog safety goggles, safety gloves, respiratory protection and chemical resistant PVC safety boots

Browse through our lab safety PPE equipment here.

The Full Guide to Design a PPE Program

Before constructing a OSHA program, the hierarchy of controls or a priority list should be written.

First of all, safety equipment is considered as the last line of defense so focus on substitution, elimination, administrative controls and engineering controls first.

Once that has been acknowledged, the employer should ensure all parties fully participate in the program, a reliable program coordinator is appointed and the PPE program is reviewed periodically.

1. Safety Awareness in PPE Program

One major factor to successfully implement an OSHA program is to raise safety awareness. This is to promote commitment to the program entirely.

So to ensure every party is aware, superiors must formulate a clear and concise company policy for all parties to follow.

2. Identifying Workplace Hazards

No matter how many safety precautions you place and practice at the workplace, hazards may still occur. Of which all must be identified and prevented accordingly.

First, revise all job operations, work practices, equipment and worksite plan. Then, apply advanced hazard analysis systems that follow Health and Safety principles. Lastly, you should review all work practices, job procedures, equipment and plant layout.

Largest global provider of Integrated Risk Management software and information services: SPHERA

Goggles

Face Shield Visor

Safety Harness

Hand Gloves

Reflective Vests

Lightweight Safety Shoes

3. Selection of PPE

Although PPE should be the last line of defense, it is the extra layer of safety every worker needs. Hence, all identified hazards must match with the suitable Personal Protective Equipment.

Moreover, to be extra safety-conscious, consult an occupational safety expert who can examine all the safety precautions and verify the PPE standards (Refer to SIRIM-QAS PPE Standards).

Also, what you can do is perform a workplace trial every so often. As for the PPE, you should always consider the ergonomic features of PPE and calculate all the costs relating to PPE usage.

4. Protective Gear Fitting

Once you’ve ticked all the boxes of which PPE is most suitable for your workers, you must ensure that the PPE fits all of them to work comfortably.

Hence, enable workers for the fitting of safety equipment and examine whether the PPE is worn properly throughout all their tasks.

5. PPE Program Training

Now that every worker has the PPE they need, they need to be trained and educated following the right safety standards.

Not only should the training apply to PPE users, PPE selectors and stock keepers should also be trained relating to the PPE. Furthermore, the training must be ongoing regularly to confirm compliance is practiced.

6. Maintenance of Safety Equipment in PPE Program

Confirm that all PPE users are familiar with the method of use, inspection and disposal of safety equipment.

In addition to that, affirm that every worker is can identify PPE defects and report to the appropriate authorities.

7. PPE Program Audit

You’re almost done with the PPE program but one thing you should be aware of is its consistent effectiveness among your workers. So, it is a good idea to revise and review the PPE program at least once a year.

Also, by analyzing the safety performance records, you can include new and improved safety rules based on those records as well.

ADDITIONAL TIPS

Upper management is responsible for the provision of safety equipment for their workers.

But, workers themselves have their own set of duties for a safe and healthy work environment.

1. Use Personal Protective Equipment properly

Make sure the PPE you are wearing fits your job description. If you are not sure or require additional safety equipment, confer the safety representative of your company.

2. Training

- Take note of all parts of the training to know the accurate way to wear, maintain and dispose of PPE.

- Participate in education and training in how to fit, wear, and maintain protective gear.

- Ask questions to make sure you know when, why and what PPE should be worn.

3. Maintenance

- Follow the PPE training biblically. It’s a matter of life or death.

- Check your safety equipment before and after every use.

- Handle PPE with care.

- Properly clean PPE after each use.

- Replace or repair damaged PPE before the next use.

- Avoid PPE from sun or contaminant exposure.

Steps to Create a PPE Program That Works

A PPE program is only successful if everyone involved cooperates and supports the initiative.

Once a well-structured program is designed, workers will know the right procedures relating to their safety equipment.

So we as the leading safety equipment and safety shoes in Malaysia provides you with a selection of safety compliant PPE that helps ensure a safe working environment.

But if you have trouble selecting, refer to How to Choose the Right PPE to know your perfect match. Because we can protect you from your head to your toes!

Buy Boxter Safety Shoes in bulk and get these amazing benefits!